ACF(Activated Carbon Fiber) Features

| Component |

Natural fiber, Artificial organic fibers throught the carbonation |

| Specific Surface Area |

1,000~1,800㎡/g |

| Pore Dia |

10~40Å |

| Adsorption |

10~100 times faster than GAC(Granular Activated Carbon) |

| Regeneration |

Available by steaming at 105~115℃ with less degradation in performance despite continuous adsorption and desorption |

Adsoption Tower Comparison between ACF & GAC

| |

ACF |

GAC |

| Absorbent material |

Activated Carbon Fiber |

Granular Activated Carbon |

| Filled Volume |

Below 1/10 ~ 1/30 |

Over 10 times than ACF's |

| Regeneration |

Short recovery time and easy(Steaming at 120℃, approx, 30min.) |

Outsourcing required(Steaming at 400℃) |

| Replacement period |

3~5 years(Supplement unnecessary) |

3~4 months (Supplement necessary 100%) |

| Solvent recovery quality |

High (No coal fly ash) |

Low (Impurities contained) |

| Electricity consumption rate |

Below 150mm Aq |

over 350mm Aq |

| Secondary pollution & Noise |

Low (Non fly ash) |

High (Fly ash generated) |

| Installation cost |

Low due to small-size facility(High initial cost acc. the absorbent material price) |

High due to large-size facility (Low initial cost, but additional cost increases) |

| Maintenance cost |

Low by reusing of generated absorbent materials |

High due to the exchange cost of total activated carbon |

ACF(Activated Carbon Fiber) Filter Specifications

ECO EN TOP is recognized by both plant is specialized in the best environment

소incineration, air, water and other food plants in the field of environment, including recycling facilities ensure superior performance by World-class environment is recognized as a plant contractor

Adsorption

The adsorption is one of deodorization methods to remove odor substances by solid adhesions with simply equipment, but not suitable for high concentration and large volume of treatment.

Activated carbon, which is applied to most gases, is used as adsorption materials. Equipment is classified to regeneration type and non-regeneration type depending on the adsorption materials.

Applications & Features

-

Regeneration type

-

: 1. High removal Rate

: 2. Various application from low to high grade in concentration

: 3. Not suitable for odor substances with non-condense components due to the necessity of a seperated process to treat gases from adsorption materials

-

Non-regeneration type

-

: 1. Regular exchange necessary of adsorption materials

: 2. Low installation cost & easy maintenance

: 3. Suitable for sites with irregular odor generation

Absorption

The absorption is an odor removal method by absorption liquid, which is the most widely used in industries.

It has low installation cost, easy maintenance and high stability, but less effective than ACF's.

Correct absorption liquid selection and appropriate equipment is the most important part for maximized result.

| Neutralizing absorbent |

Acid : Dilute sulfuric acid, Hydrochloric acid

Alkali : Caustic soda

|

| Oxidizer |

Hypochlorous Acid Water, Chlorine water, Chlorine disxide, Porassium permanaganate etc. |

| Solvent |

Nonvolatille petroleum, Esters |

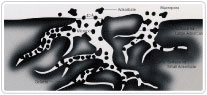

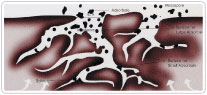

Activated Carbon Adsorption & Desorption System

Features & Structures

-

99% removal rate of odor and VOC(Volatile Organic Compounds)

Combination of activated carbon adsoprtion and desorption system

Compact and integrated structure

Long life (regeneration) of activated carbon

Low maintenance cost

Easy management by catridge type of activated carbon

Applications

Features & Structures

-

Printing facilities

Painting facilities

Fermentattion facilities

Sewage & wastewater treatment facilities

Excreta & livestock wastewater treatment facilities

Various VOS & odor regeneration facilities